Ijubane lendiza yesimanje selifinyelele izikhathi ezingaphezu kuka-2,7 kunejubane lomsindo.Ukundiza okunjalo okunamandla amakhulu kuyobangela indiza ukuba igudle umoya futhi ikhiphe ukushisa okukhulu.Uma isivinini sendiza sifinyelela izikhathi ezingu-2.2 zejubane lomsindo, ingxubevange ye-aluminium ayikwazi ukumelana nayo.Kufanele kusetshenziswe ingxubevange ye-titanium ekwazi ukumelana nokushisa okuphezulu.Okulandelayo, Uchwepheshe ovela eMnyangweni Wezobuchwepheshe we-RSM uzokwabelana ngesizathu sokuthi kungani okuhlosiwe kwe-titanium alloy kubalulekile emkhakheni wezindiza!

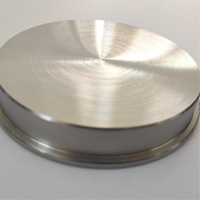

Lapho isilinganiso sokuphonswa kwesisindo se-aeroengine sikhuphuka sisuka ku-4 siye ku-6 siye ku-8 siye ku-10, futhi izinga lokushisa le-compressor outlet likhuphuka ngokufanayo lisuka ku-200 liye ku-300 ℃ laya ku-500 liye ku-600 ℃, i-low-pressure compressor disk kanye ne-blade ekuqaleni yenziwe i-aluminium kufanele ishintshwe nge-titanium alloy.

Eminyakeni yamuva, ososayensi baye benza intuthuko entsha ocwaningweni lwezakhiwo ze-titanium alloys.Ingxubevange ye-titanium yasekuqaleni eyakhiwe nge-titanium, i-aluminium kanye ne-vanadium inezinga lokushisa eliphezulu lokusebenza elingu-550 ℃ ~ 600 ℃, kuyilapho ingxubevange esanda kwakhiwa ye-aluminium titanate (TiAl) inezinga lokushisa eliphezulu lokusebenza elingu-1040 ℃.

Ukusebenzisa ingxubevange ye-titanium esikhundleni sensimbi engagqwali ukwenza amadisks nama-blades okucindezela okuphezulu kunganciphisa isisindo sesakhiwo.Uphethiloli ungonga ngo-4% kukho konke ukuncipha ngo-10% kwesisindo sendiza.Ngerokhethi, njalo ukwehliswa kwe-1kg kungakhuphula ibanga ngo-15km.

Kungabonakala ukuthi izinto zokucubungula i-titanium alloy zizosetshenziswa ngokuqhubekayo endizeni, futhi abakhiqizi abakhulu be-titanium alloy kufanele bazinikele ocwaningweni nasekuthuthukisweni nasekukhiqizeni ama-alloys e-titanium asezingeni eliphezulu ukuze kuqinisekiswe indawo emakethe ye-titanium alloy.

Isikhathi sokuthumela: Sep-06-2022